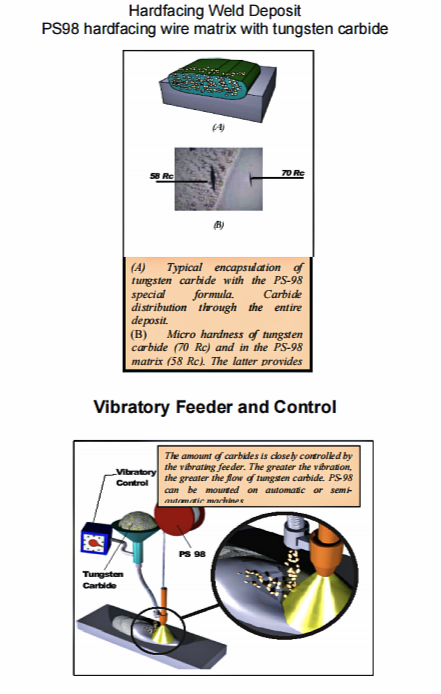

At Ningbo For-Global, we have tungsten carbide hardfacing technology as illustrated, using a PS98 hardfacing wire matrix with uniformly distributed tungsten carbide particles. Through controlled weld deposition, carbide is enc apsulated throughout the entire hardfacing layer, forming high-performance wear parts with consistent structure.

The tungsten carbide reaches a hardness of up to 70 HRC, while the PS98 matrix provides a supportive hardness of approximately 58 HRC, ensuring an effective balance between abrasion resistance and structural toughness for demanding applications.

A precisely controlled vibratory feeder system regulates the amount and distribution of tungsten carbide during welding. By adjusting vibration frequency, carbide feed can be accurately controlled, enabling stable and repeatable production of carbide-reinforced wear parts in automatic or semi-automatic welding processes.

We take pride in mastering this hardfacing technology and applying it to manufacture durable tungsten carbide reinforced wear parts designed for long service life under high-wear conditions.

Contact: Kevin Dai

Phone: (86)136-05749661

Tel: (86)574- 82815688

Email: kevin.dai@for-global.com

Add: Hehua Bridge Industrial Zone, Yunlong Town, Ningbo City, China, 315135

We chat